Press release Rapid.Tech 3D 2024

How is additive manufacturing succeeding for series production in the automotive industry?

Experts from companies including Audi, BMW, Brose, EDAG, Honda, Mercedes-Benz and Schaeffler to discuss at the Mobility forum on 16 May.

-

EDAG-Constellium-FhgIWU - wheel carrier -

NeoTech_AMT

“Additive manufacturing is a new discipline in the automotive industry and there are no established supply chains yet. This makes it even more important for all those involved in product development and production to discuss requirements and potential applications so that we can drive forward the use of AM in series production. The forum promotes open discussion, which will enable us to identify adjustments that still need to be made,” say Frank Cremer, Direct Sales Manager for 3D Printers at 3D Systems, and Maximilian Binder, Project Manager for Additive Manufacturing at the BMW Group. Frank Cremer has overseen the content of the Mobility forum for many years, and as of this year, Maximilian Binder will be providing a perspective from car manufacturers in particular. Both are members of the Rapid.Tech 3D advisory board.

Keynote from BMW on the use of additive manufacturing for cast components

The importance of additive manufacturing for the automotive industry will be emphasised in the keynote speech that opens the final day of the 20th Rapid.Tech 3D. Jochen Wendling from the BMW plant in Landshut will report on the large-scale production of additively manufactured inorganic sand cores for the casting of cylinder heads. Because the traditional core production process involves among other things a high level of investment in geometric tools, BMW and its partners have developed and implemented an automated process. Importantly, this allows for greater design freedom and optimises production.

Mercedes-Benz uses additive manufacturing for lighting applications

Pascal Boley, a PhD student in Research and Development at Mercedes-Benz, explains how the company uses additively manufactured optical components to develop of automotive lighting applications. He demonstrates how the use of free-form optics allows increasingly complex components to be positioned in specific locations around the vehicle using light. Mercedes-Benz is trialling DLD (Digital Light Processing) for the production of functional prototypes. Compared to familiar approaches using stereolithography (SLA) or polyjet modelling (PJM), DLD has not yet been researched in detail.

Schaeffler highlights the added value of additive multi-material manufacturing

Carsten Merklein, Head of the Advanced Manufacturing Technologies Department, and Florian Dörrfuss, Head of Additive Manufacturing at Schaeffler Sondermaschinenbau, explain why additive multi-material manufacturing delivers added value both technically and financially for Schaeffler as a user and as a mechanical engineering provider. The motion technology company’s mechanical engineers have developed a multi-material laser powder bed fusion system, the first simultaneous multi-material printing solution for industry. The two speakers will present a design for a holistic multi-material additive manufacturing production system and explain how it is integrated into Schaeffler’s overall strategy.

Audi reports on additive manufacturing in prototyping and toolmaking

In his presentation, Martin Bock, overall project manager for Audi’s metal 3D printing centre, will provide an update on the latest developments in prototyping and tool production. He will report on progress with additive manufacturing in the automotive sector and offer insights into metal and plastic 3D printing.

Honda attends Rapid.Tech 3D for the first time

Japanese car manufacturer Honda is taking part in the Mobility forum at Rapid.Tech 3D for the first time. Kotaro Muraoka, Head of Additive Manufacturing Production Technology, will share insights into Honda’s use of additive technologies in the production process. The car manufacturer considers additive manufacturing a core technology and is currently supporting research and development in the field.

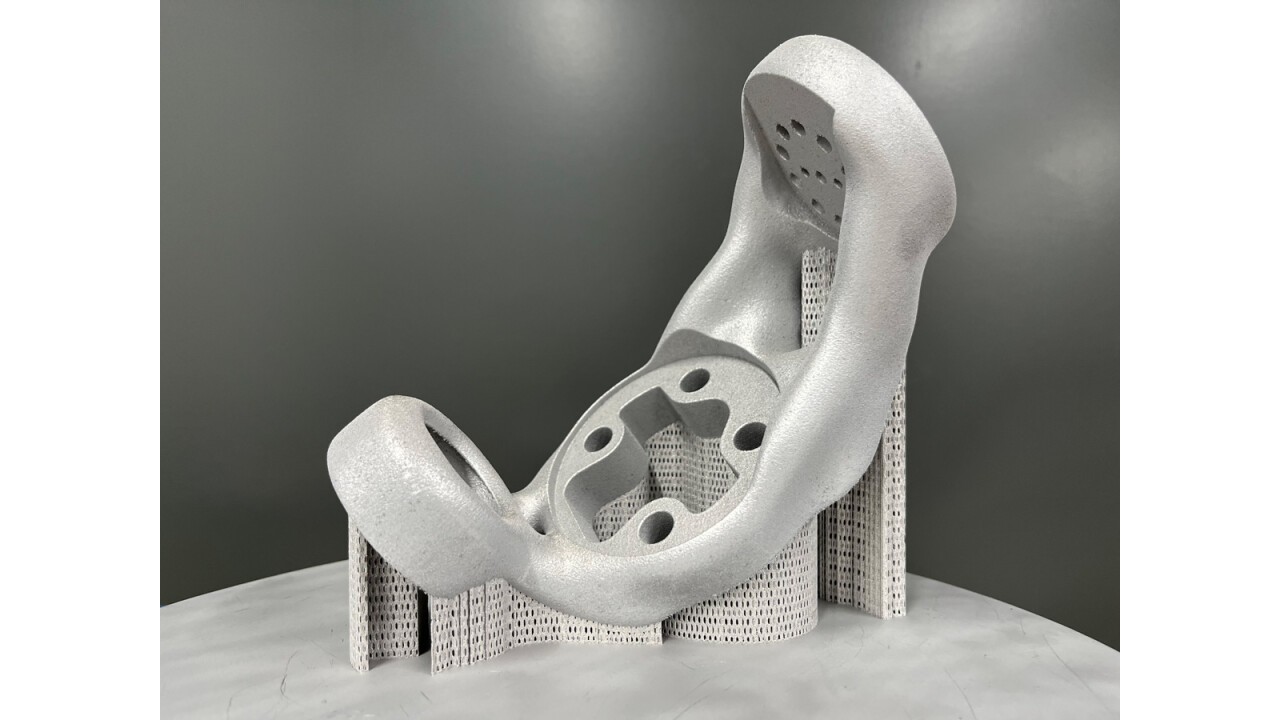

EDAG, Constellium and Fraunhofer IWU: creating a flexible robotic vehicle with additive manufacturing

Richard Kordaß, Project Manager for Innovations at EDAG, Syam Unnikrishnan, Business Development Manager at Constellium, and Thomas Töppel, Deputy Head of the LPBF Department at Fraunhofer IWU, demonstrate how additive manufacturing can help a multifunctional robotic vehicle adapt quickly to different transport needs. Taking the wheel carrier component of the vehicle known as the EDAG CityBot as an example, they present a process chain for automated and rapid component development and the selection of appropriate manufacturing processes and materials.Laser Powder Bed Fusion (LPBF) combined with Constellium Aheadd® CP1, an aluminium alloy specially developed for the LPBF process, has proven to be financially and technologically beneficial.

The Brose path to additive series production

Automotive supplier Brose uses 3D printing to produce functional prototypes and production fixtures, as well as for the cost-effective manufacture of small series and niche products.

The joint presentation by Dr Jan Sander and Christian Kleylein, experts in additive technology at Brose, will provide an insight into the company’s journey towards additive series production. The first spare parts series was produced in 2019. One year later came the breakthrough in additive series production, of housing for the electric air conditioning compressor. The production of a dowel, a standard component in vehicle seats, with 3.6 million units created over its lifetime, blazed a trail for the industry.

Brose also uses additive manufacturing for other mobility solutions such as e-bikes. The company will be exhibiting a prototype e-bike with a 3D-printed frame at Rapid.Tech 3D.

Discussion: is spare parts production at the touch of a button a realistic prospect?

The forum will close with a discussion among speakers and participants on the progress and challenges of the use of additive manufacturing in the sector. The aim will be to answer the question: is spare parts production at the touch of a button a realistic prospect?

Specialist conference with eight industry and science forums

Alongside the Mobility trade forum, other forums at the Rapid.Tech 3D specialist conference will provide insights into the latest developments and applications in additive manufacturing. On the first day of the event (14 May 2024), the AM4industry format organised by the Additive Manufacturing Working Group of the German mechanical and plant engineering association VDMA will welcome visitors for the first time. The established Aerospace forum is also set to take place that day, as is the Additive Manufacturing Science forum, which will continue into day two (15 May 2024). Day two will see the Chemical and Process Engineering forum, presented by DECHEMA, the Software, AI and Design forum. The Innovations in Additive Manufacturing forum will also run on day two, continuing on day three (16 May 2024). The Mobility and AM Science by Fraunhofer forums will also take place on the final day.

About Rapid.Tech 3D:

In just two decades, Rapid.Tech 3D – with the specialist conference as its centrepiece – has become one of Central Europe’s leading additive manufacturing trade events. This year’s event will be held from 14 to 16 May at Messe Erfurt.

More at: www.rapidtech-3d.de/en

About Messe Erfurt GmbH:

Central Germany’s largest trade show and conference venue, Messe Erfurt has established itself as a forum for businesses, scientists, doctors, trade unions and many other institutions. Every year, it hosts over 220 events, conventions, conferences, trade fairs, exhibitions, corporate events and concerts, attracting over 650,000 visitors.

More at: www.messe-erfurt.de/en/

Trade Media Contact

Ina Reichel

- Freelance Journalist -

Mob: +49 172 602 94 78

inareichel@ma-reichel.de